A Better Way to Get Things Done: Refractory Insulation

The faster the refractory installation, maintenance or repair, the more efficient

and, by extension, profitable the company as savings fall to the bottom line

Manufacturers that rely on industrial-grade furnaces, boilers and incinerators to produce their quality products are always looking for ways to improve. It’s how they stay relevant and, more importantly, profitable. But you don’t get better just by desiring it. You need to identify better ways to get things done and introduce risk-neutral change to current operational processes. By some estimates, inefficient processes can reduce a company’s profitability by as much as one-third.

Given refractories’ importance to safeguarding an operation’s multimillion-dollar thermal-processing equipment, and to avoid unscheduled downtime, it’s smart business to have a sustainable maintenance and repair process in place. When a refractory situation does arise, however, the more proficient the process solution the better.

Controlling the Heat

Furnace design is largely about controlling heat to maximize energy efficiency. An energy source – whether that is gas, coal, wood or electricity – is used to heat the furnace, and the furnace lining is designed to keep that heat inside the furnace. There are other factors to be considered, such as the environment inside the furnace, whether there is any abrasion or chemical interactions, or whether the furnace maintains a steady-state temperature or undergoes temperature cycles. Regardless of what considerations have to be made for the hot-face lining, an insulation package must be used to reduce fuel consumption and control the cold-face temperature.

There are a large variety of insulation packages and materials that can be used in furnace design. Insulation comes in the form of board, fiber, brick and castables. Each type of insulation comes with its own sets of considerations, such as insulation value, installation method and cost. When considering the insulation package for the vertical wall of a furnace, support must also be considered because the insulation is expected to stay where it is placed and not slump over time. There also must be a means of connecting the hot-face working lining to the furnace structure to provide support. This is accomplished with an anchoring system that connects to the furnace shell and penetrates some distance into the dense hot-face working lining.

Anchoring Systems Challenge Insulation Installations

Anchors are considered to be the bones of a refractory installation and have several functions. They hold the refractory to the wall to keep it from falling in. They also prevent wall buckling due to the internal thermal stresses created by high temperatures. And, to a lesser degree, anchors can also help support the load of the refractory weight.

The anchoring system, however, can present big challenges when installing or maintaining the insulation. In most furnace applications, anchors are first welded directly to the furnace shell. Next, the insulation package is installed and finally the working lining. With anchors sticking off the furnace shell, installing insulation can become a challenge.

Fiber Insulation in the form of blanket can be pressed into the gaps between the anchors, but it is important that the insulation remain in place during the life of the furnace. Industrial furnaces tend to vibrate, either from use of combustion or exhaust blowers or other process equipment. This constant vibration can cause fiber insulation to slump and lead to hot spots in the furnace wall due to the lack of insulation.

Insulation Boards is rigid enough to support itself on its end and can be found in a variety of densities and thicknesses to obtain the required insulation value. However, insulation board typically comes in sheets that will have to be cut to fit around the anchors. This can result in a significant amount of manpower and a significant amount of time in a furnace installation. The downtime of an industrial furnace can be costly, which often results in tens of thousands of dollars per hour in lost profits. For this reason, companies try to minimize the time spent rebuilding a furnace. Fewer man-hours on a rebuild also tends to reduce the overall cost of the project.

Ultra-Lightweight Refractory Gunnites offer a means of installing a large amount of insulation in a relatively short period of time. A gunnite is a monolithic refractory castable that is pumped dry through a hose under pressure and is mixed with water at the nozzle. Once the wet castable impacts the surface, it stiffens quickly to avoid slumping and hardens as it dries. This means that the gunnite could be installed over the anchors with minimal time. The installer only needs to wrap the end anchors with masking tape to keep them clean for the working lining.

Distinct Differences in Refractory Gunnites

Ultra-lightweight castables are a sub-set of the lightweight castables category but with a very important difference: density. For example, the average lightweight castable with a maximum service limit of 2400°F typically has a density of about 80-90 pcf (pounds per cubic foot). By comparison, ultra-lightweight castables with a maximum service limit of 2400°F will have a density of about 25-30 pcf.

This important distinction comes into play when you are looking at your insulation thickness and calculating your cold-face temperature. At the stated densities in a furnace operating at 2000°F, it would take nearly three times more lightweight castable than an ultra-lightweight castable to achieve the same cold-face temperature – making many ultra-lightweight castables perfect for insulation and most lightweight castable refractories impractical to use as part of your total insulation package.

Ultra-lightweight castables that achieve final densities of 25-30 pcf while offering service temperatures above 2400°F are available through various refractory manufacturers. One such product, Plicast Airlite 25 C/G (aka Liquid Board™) from the Plibrico Company, is designed to be installed via casting or gunnite using conventional gunnite equipment. Featuring low thermal conductivity and excellent thermal-shock resistance, Plicast Airlite 25 C/G is durable and quick to install. It also has distinct advantages over insulation board, which has a labor-intensive installation process of cutting around all the welded anchors, and fiber insulation, which can experience frequent hot spots due to slumping insulation. With an ultra-lightweight, Liquid Board-type of castable, it is possible to attain required insulation values and extended lining life with the installation speed of a refractory gunnite.

Working With, Not Against, the Anchoring System

Let’s consider a real-life production furnace operating at 2000°F with a simple 9-inch refractory lining consisting of 6 inches of dense refractory and 3 inches of insulation. For comparison, we will assume an ambient air temperature of 81°F and eliminate any effects of exterior wind velocity. The dense refractory working lining for these examples is Pligun Fast Track 50, a 50% alumina, 3000°F-rated refractory gunnite.

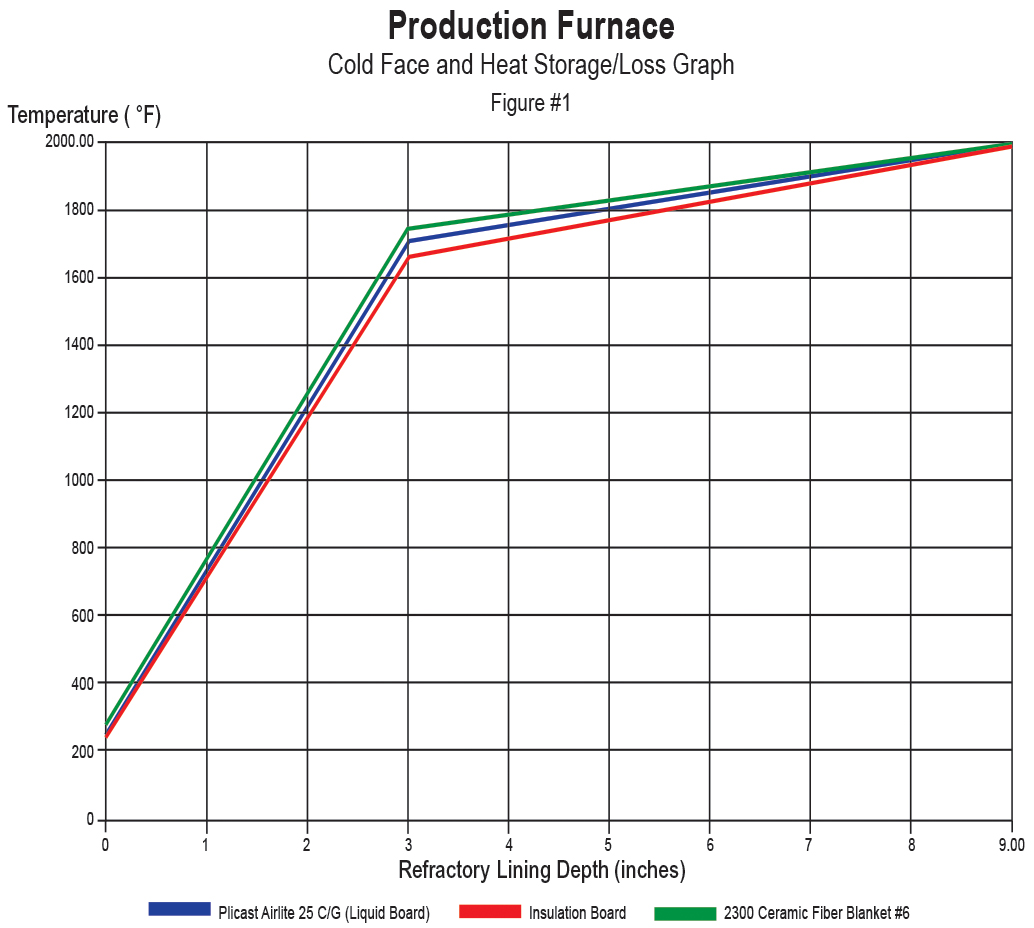

As seen in Fig. 1:

- Using 3 inches of ceramic fiber blanket at a density of 6 pcf, a cold-face temperature of 252°F can be achieved.

- Using 3 inches of insulation board at a density of 26 pcf, a cold-face temperature of 247°F can be achieved.

- Using 3 inches of an ultra-lightweight gunnite such as Plicast Airlite 25 C/G with a maximum service temperature of 2500°F and assumed density of 25 pcf, a cold-face temperature of 262°F is expected.

The calculated difference in cold-face temperature between insulation board and the ultra-lightweight gunnite is 15°F, but the difference in installation time savings could be multiple shifts.

The cost of downtime can be incredibly high for any manufacturer, especially since downtime can result in a series of costs and losses (both tangible and intangible), including production, labor, replacement costs, product losses and, if unexpected, reputation damage. Industry resources estimate downtime can cost thermal-processing companies between $250,000 and $1 million per hour. When multiplied over several shifts, this could mean millions of dollars in downtime costs. Not to mention that labor is a major contributor to the overall cost of a refractory project. The quicker the refractory installation, the less downtime and the more profitable the company.

For example, in an approximately 750-square-foot round duct application (cylinder) with anchors already installed, on average, installation of 4 inches of the different insulation types can be estimated at:

- Fiber Insulation: 137 total labor hours, or ~5.5 square feet/hour

- Insulation Board: 288 total labor hours, or ~2.6 square feet/hour

- Ultra-Light Gunnite/Liquid Board: 80 total labor hours, or ~9.4 square feet/hour

The quick and easy installation of the ultra-light gunnite/Liquid Board represents an average estimated financial savings in downtime of between $35 million and $130 million – savings that drops directly to a company’s bottom line. The time compression of installing gunnite also holds an added advantage for the insulation installer because labor man hours can come with a premium price tag and can sometimes be in short supply. All of this makes the ultra-lightweight gunnite/Liquid Board an excellent choice to minimize downtime and rebuild costs while meeting the furnace design criteria..

An Efficient Solution

Manufacturers that rely on industrial-grade furnaces, boilers and incinerators to produce their quality products are constantly looking for ways to reduce costs, increase profits, and improve efficiencies by looking at and introducing risk-neutral change to current processes. Maintaining efficiency and avoiding unscheduled shutdowns of heat-processing equipment requires maintenance. Selecting quality materials and a risk-neutral installation process that minimizes maintenance completion times, such as ultra-light gunnite, can help companies become more efficient.

Incorporating ultra-lightweight gunnites into furnace refractory linings presents a transformative approach to insulation installation. By significantly expediting the installation process, these materials offer not only increased efficiency but also substantial cost savings through reduced downtime.

The distinct advantages of ultra-lightweight castables, exemplified by products like Plicast Airlite 25 C/G, include remarkable durability, low thermal conductivity, and robust thermal shock resistance. In contrast to labor-intensive insulation board and the potential drawbacks of fiber insulation, ultra-lightweight gunnite stands out as a game-changer. With estimated downtime costs ranging from millions to hundreds of millions, the adoption of ultra-lightweight gunnite promises not only enhanced profitability but also an innovative way forward for refractory insulation in industrial furnaces.

.

For more information contact the Plibrico Company at contact@plibrico.com, or 312-337-9000.

Plibrico Company, LLC

Plibrico Company, LLC Plibrico Company, LLC

Plibrico Company, LLC