Redi-Shapes Custom-Engineered Precast Refractory Shapes

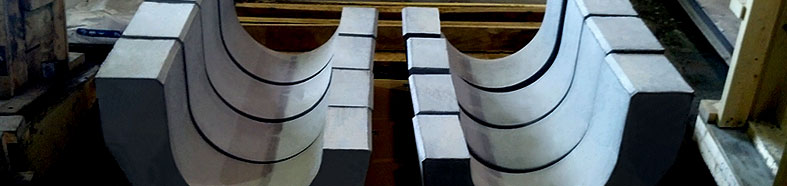

Plibrico Redi-Shapes® precast shapes provide fast refractory lining replacement in recurring high-wear zones. Our high-quality, custom-engineered Redi-Shapes are formed to your exact specifications. Ready to install, Redi-Shapes reduce downtime that result in lower repair costs.

Plibrico’s expertise in precast shape manufacturing allows us to match your specific critical wear zones. Redi-Shapes are tailor-made for your furnace or boiler, in any size or configuration. Our in-plant manufacturing conditions enhance consistent production, and Plibrico’s molds are engineered to insure perfectly contoured, dimensionally accurate block every time. Our capabilities range from 10 lb. bricks to 15,000 lb. engineered block.

Redi-Shapes precast shapes are manufactured from Plibrico’s high-quality castable and plastic refractory materials. Plibrico refractories control heat loss, and overcome the problems imposed by controlled atmospheres or reactive environments. Redi-Shapes can be manufactured and zoned in your furnace to resist specific problem areas such as abrasion, erosion, thermal shock and metal and slag penetration. Custom firing also optimizes shape properties for specific applications.

Redi-Shapes precast shapes allow you to isolate repairs and get back to service fast. Confining replacement work to high-wear areas eliminates costly, time-consuming tear-outs of major portions of the adjacent refractory lining. Quick installation of Redi-Shapes reduces downtime and saves on labor costs. Redi-Shapes are ready for immediate installation when delivered, and can be kept in inventory and used when repairs are needed.

Aftermarket Boiler and Furnace

Repair Kits

Plibrico provides high-quality refractory aftermarket repair products for Cleaver-Brooks boilers, Hurst boilers and Lindberg heat treating furnaces.

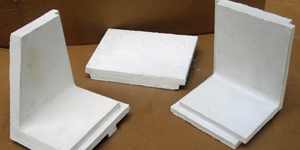

Replacement Tile Kits for Cleaver-Brooks Boilers

Plibrico offers aftermarket replacement tile kits for Cleaver-Brooks package boilers. Backed by our extensive knowledge of refractory technology, and our expertise in refractory shape manufacturing, Plibrico is well-positioned to provide high-quality replacement tile kits that are designed and manufactured for a true fit.

Replacement Grates for Hurst Boilers

Plibrico manufactures Hurst boiler aftermarket replacement cast grates that stand up to OEM specifications. Built from Plibrico’s quality refractory materials, our aftermarket boiler grates are made to fit all standard widths of Hurst boilers. Our in-plant manufacturing operation provides quick turnaround and superior customer service to meet all of your Hurst boiler grate needs.

Plibrico manufactures Hurst boiler aftermarket replacement cast grates that stand up to OEM specifications. Built from Plibrico’s quality refractory materials, our aftermarket boiler grates are made to fit all standard widths of Hurst boilers. Our in-plant manufacturing operation provides quick turnaround and superior customer service to meet all of your Hurst boiler grate needs.

Replacement Refractory Products for Lindberg Heat Treating Furnaces

Produced to fit any Lindberg furnace shape or size specification, Plibrico manufactures aftermarket refractory furnace linings, tiles and precast shapes for Lindberg heat treating furnaces. Our furnace refractory replacement products are built to withstand the extreme temperatures and abrasion associated with the heat treating process. Plibrico will also provide the design and installation services you will need for your specific Lindberg furnace application.

Produced to fit any Lindberg furnace shape or size specification, Plibrico manufactures aftermarket refractory furnace linings, tiles and precast shapes for Lindberg heat treating furnaces. Our furnace refractory replacement products are built to withstand the extreme temperatures and abrasion associated with the heat treating process. Plibrico will also provide the design and installation services you will need for your specific Lindberg furnace application.