Refractory Products for Aluminum

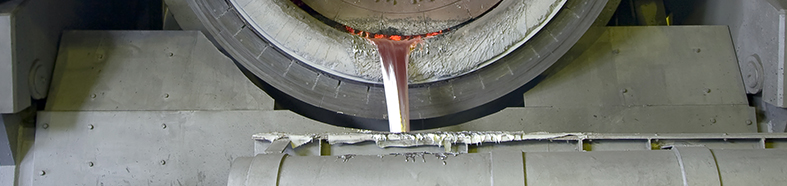

Plibrico is a major supplier of monolithic refractory materials for the aluminum industry. We were the first to introduce a complete line of non-wetting aluminum contact castable refractories. Our Al-Tuff® series of non-wetting refractory materials were designed specifically to provide an effective and economical solution for aluminum applications. The Al-Tuff series features products that are modified with a non-wetting additive for aluminum contact. The modified surface increases wetting resistance and reduces the potential for oxidation reduction.

View our Al-Tuff series for aluminum processing.Plibrico also offers Al-Shield™ castable refractories and gun mixes designed and engineered specifically for high-temperature and aggressive aluminum alloys and contact areas. Al-Shield aluminum-resistant refractories contain aluminum-resistant additives that create a barrier – the additive compound reacts with aluminum to form a dense barrier layer. Our Al-Shield refractories provide longer service life that results in less downtime.

View our Al-Shield series for aluminum processing.To complement our Al-Tuff and Al-Shield series of aluminum contact materials, Plibrico also has phosphate-bonded castables, gun mixes and plastic materials suitable for metal contact and all other areas in an aluminum furnace. Plibrico’s Exo-Set™ UNO series of castables and gun mixes are single component, “just add water” phosphate-bonded mixes for quick, easy and safe installation.

View our Exo-Set UNO series for aluminum processing.

Contact your local Plibrico PliPartner today for a FREE evaluation of your aluminum processing operations.

Plibrico Turnkey Refractory Solutions

Plibrico’s experienced team of refractory specialists, or PliPartners, provides complete turnkey solutions for your unique mineral processing application. From quality refractory materials to installation, repair and design services, our nationwide network of PliPartners are your single-source for reliable refractory solutions.

Quality Refractory Materials

Plibrico will analyze your operations and recommend the best refractory materials to meet your most demanding thermal requirements. Our stringent quality control policy ensures that our refractories will perform with excellence.

Quick and Reliable Delivery

Plibrico offers quick and reliable refractory material delivery – we will ship and deliver your material when you need it most.

Service and Engineering

Our refractory engineers will work with you to recommend the best solution for your unique challenge. And, you can count on Plibrico’s experienced installation and repair team to provide safe and efficient maintenance services. We are committed to successfully completing your refractory project, no matter how large or small, on time and on budget.

Learn more about our services and engineering expertise

Contact your local Plibrico PliPartner today to learn more about Plibrico’s refractory materials for mineral processing.

*NEW Refractories Selection Guide

This guide helps you to quickly and easily find the best refractories for your specific application.